Airlines were warned to check aircraft wiring in the cargo holds of Boeing 777s after a short circuit on an Etihad Airways flight prompted an emergency landing and highlighted a potentially dangerous manufacturing defect.

The Etihad crew declared a MAYDAY after detecting smoke and receiving a cargo fire warning caused by arcing from an incorrectly installed wiring harness.

The wiring had chafed on a screw and turned out to the fifth incident involving chafed cargo hold wiring reported to Boeing, according to a report released Wednesday by the Australian Transport Safety Bureau.

As a result, the manufacturer issued a fleet communication to Boeing 777 operators world wide warning them of the potential problem and followed up with a service bulletin covering about 1500 777-200, 777-200LR and 777-300ER aircraft.

It also introduced additional inspections on its production line and was considering installation and design changes to alter the position of the wiring harness on new production aircraft, the report said.

The Etihad Boeing 777-300ER carrying 349 passengers and 16 crew was northwest of Adelaide on a scheduled passenger service from Abu Dhabi to Sydney in October, 2017, when the flight crew noticed a burning smell coming from a vent.

Shortly afterward, a fire alarm sounded and master warning message “FIRE CARGO FWD” flashed up on the engine-indicating and crew alerting system.

READ: CSIRO scientist says MH370 unlikely to be north or south of existing search area.

The crew ran through a non-normal checklist and armed cargo fire switches, with shut down a recirculation fan and closed air vents in the forward compartment, and discharged two fire extinguishers in the forward hold.

They declared a MAYDAY and a second flight crew coming off a rest period were briefed and took control of the aircraft, conducting an emergency descent to 12,500ft and diverting to Adelaide.

Because there were no signs of fire when the plane landed, the passengers and crew performed a “rapid deplane” using mobile stairs — rather than an emergency evacuation —and there were no injuries.

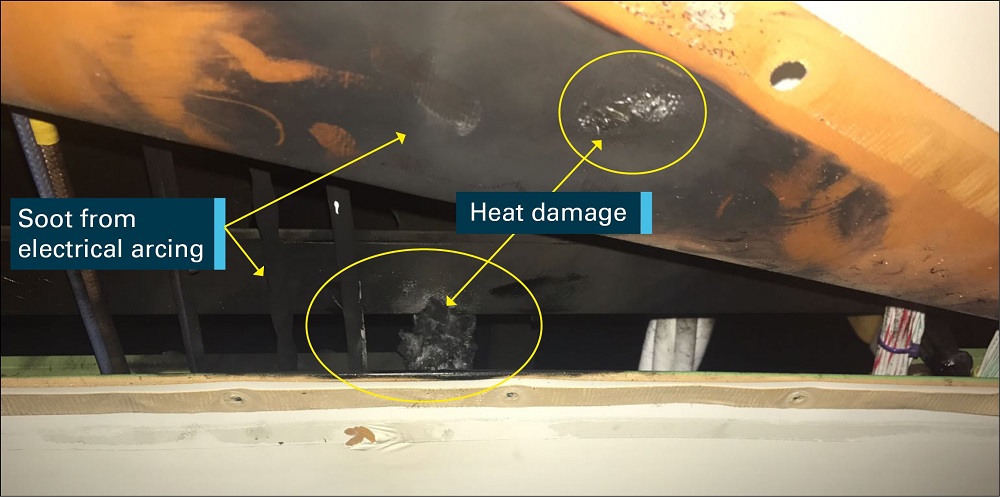

An inspection of the cargo bay found a small quantity of soot in the ceiling area as well as between the lower side of the cabin floor and the upper side of the cargo ceiling panel.

It also found a chafed 115-volt electrical wire in a wiring loom supplying the lower right recirculation fan.

Investigators said the crew had taken appropriate action to manage the situation and arming the forward cargo fire suppression system had cut electrical power to the recirculation fans preventing further arcing and damage.

A more detailed engineering inspection found the wiring bundle had been incorrectly routed and wires had come in contact with screws used in the cargo ceiling panel.

“Over a prolonged period of time, the 115V recirculation fan wire located within that bundle chafed through the insulation coating, allowing the wire to short circuit,’’ the report said, noting the significant heat generated by the short circuit damaged brackets and a carbon fiber beam.

Boeing found the wiring loom was likely to have been incorrectly positioned when the aircraft was built in 2013.

“Boeing reported that this was the fifth reported incident involving wire chafing and arcing in the cargo area of a Boeing 777 aircraft,’’ the ATSB report said. “However, this was the first event that triggered the cargo fire warning system and that had been detected in flight. In all of these cases, the wiring loom had been installed incorrectly during manufacture, allowing screws to chafe wires and short circuit.”

While classifying the incident as serious, investigators said the severity of damage was minimized through regulatory design requirements, the materials used in the aircraft, system protections and crew actions.

“In response to this, and four other incidents, the aircraft manufacturer utilized their system of communication to alert all operators of the issue and took actions in an effort to prevent reoccurrence,’’ they said in a safety message. “Regardless of this, operators and maintenance providers are another line of defence for detecting errors.

“Due diligence during scheduled aircraft maintenance and defect rectification will assist with ensuring that aircraft systems meet the design intent and function accordingly.”